Facilities

Here at Tubesheet we continually invest in our facilities and have gained a global reputation for utilising modern equipment, providing increased accuracy, higher production speeds and greater flexibility.

We can guide, provide advice and assess your individual manufacturing requirements.

Here at Tubesheet we continually invest in our facilities and have gained a global reputation for utilising modern equipment, providing increased accuracy, higher production speeds and greater flexibility.

Our team of qualified metallurgists can guide, advise, and assess your individual manufacturing requirements.

We have the facility to mill and drill components up to 3150mm long x 2100mm wide using ‘state-of-the-art’ machining centres, giving us the ability to supply fully finished components.

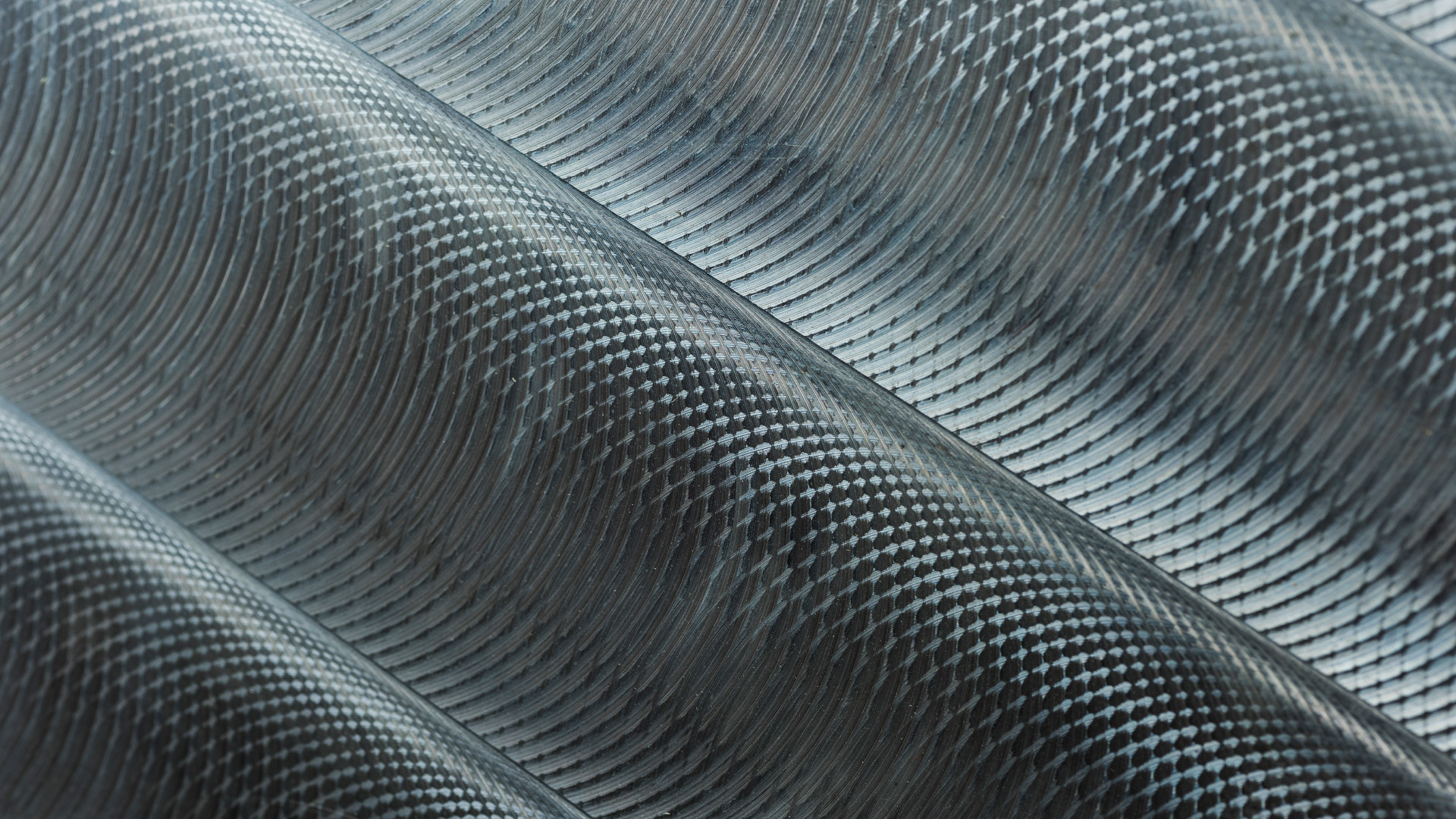

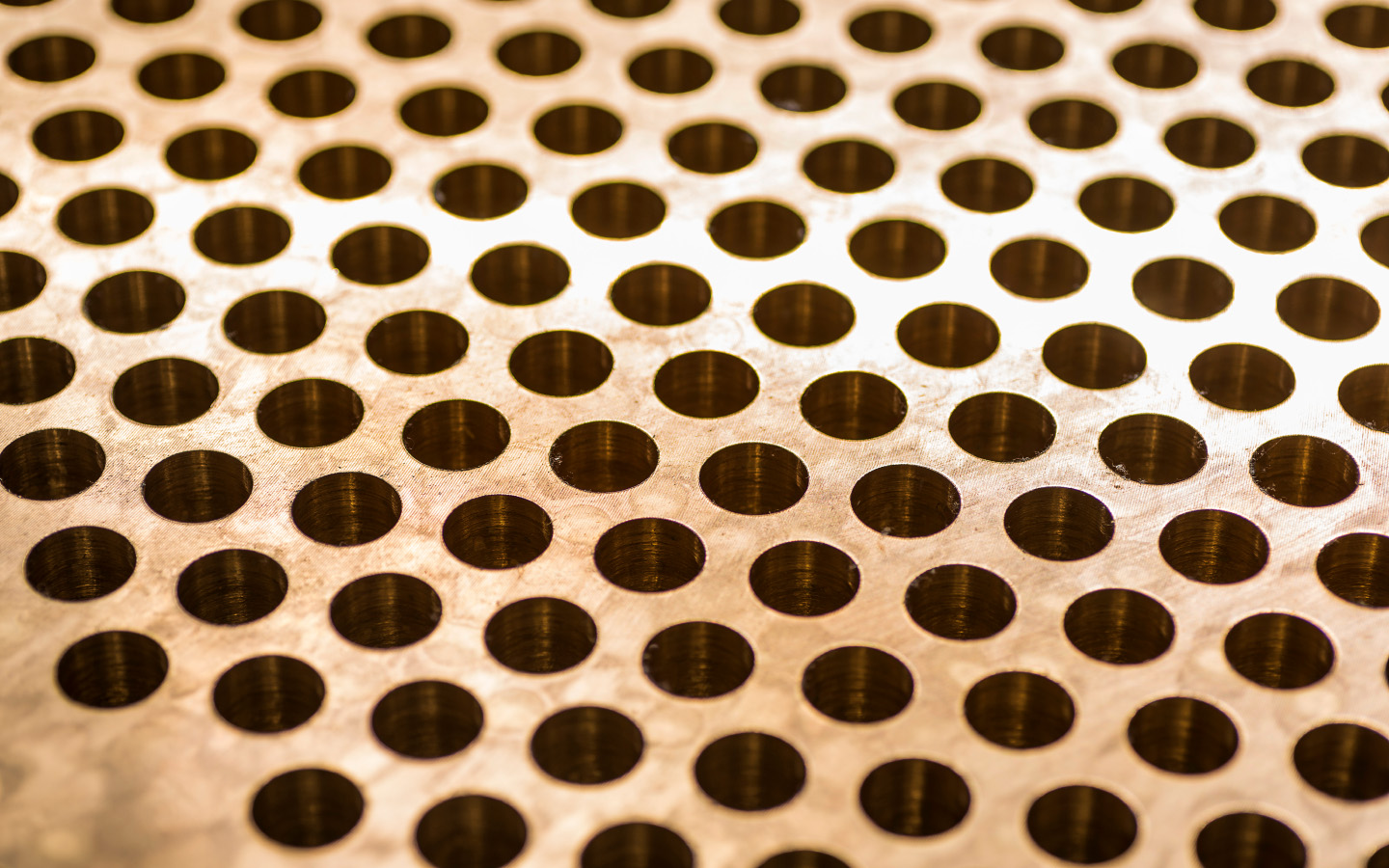

Sawing Facilities

We provide plates up to 5000mm long and 120mm thick, which are cut using the very latest saw technology. We have two automated CNC cutting machines allowing us to keep up with all demands placed upon us.

Sawn tolerances can be as close as +/-0.25mm with an alignment feature, ensuring all corners are exact and true at 90 degrees

Discs up to 2200mm diameter x 200mm thick weighing up to 5 tonnes can be produced.

A computer optimisation programme plots best yield, giving us the opportunity to pass these cost savings on to you.

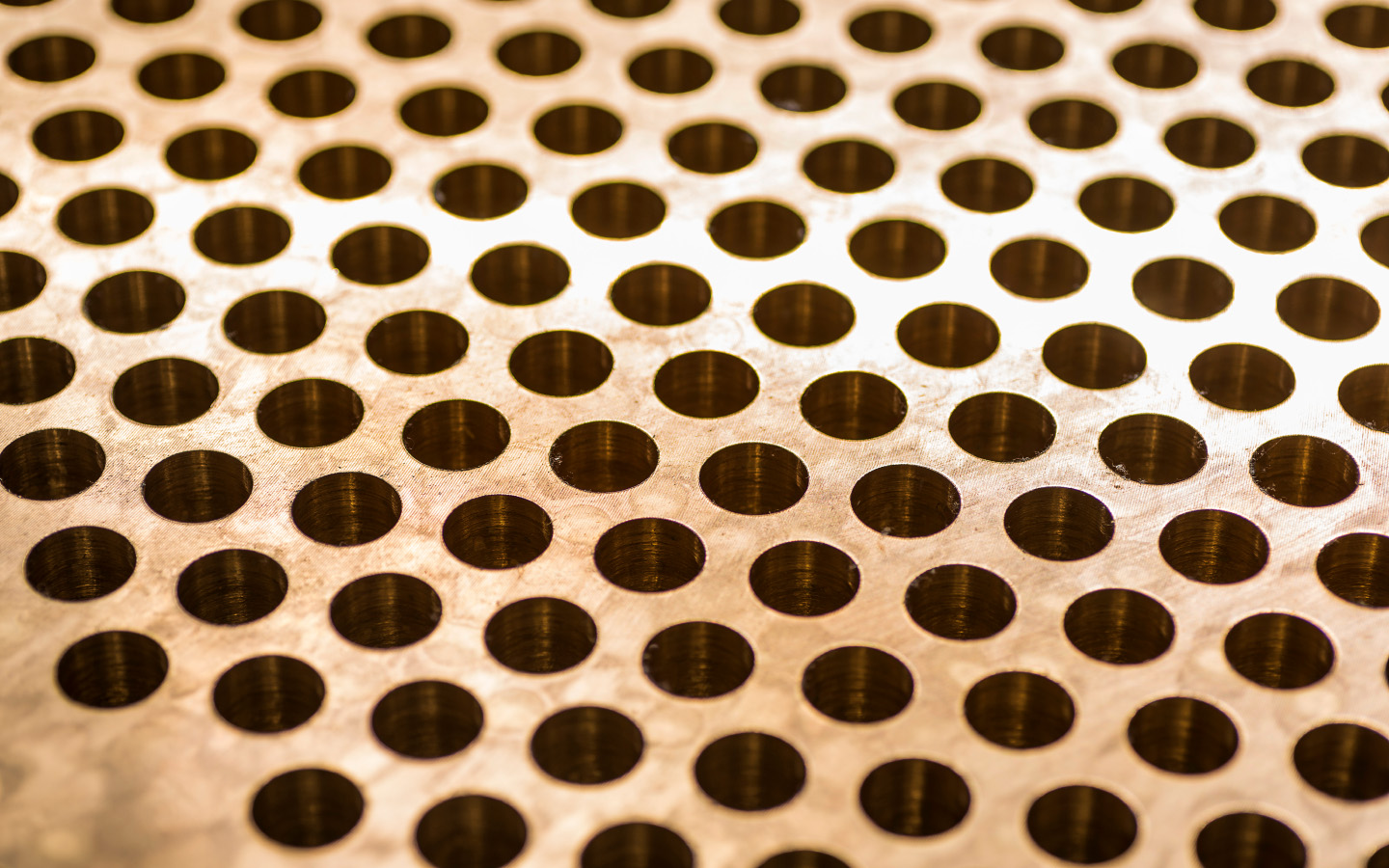

Machining Facilities

Over the past 20 years we have invested in plant and machinery in excess of GBP 5M and will continue to do so at the same or increased level. This allows us to maintain competitive edge both locally and worldwide.

We have the facility to mill and drill components up to 3150mm long x 2100mm wide using CNC machining centres, giving us the ability to supply fully finished components from our material stock inventory or from customers’ free issue material

Large and small turning capabilities are served by CNC and manual vertical borers and horizontal lathes allowing us to supply small threaded bar all the way up to tubesheets at 2000mm diameter.

Ongoing Investment

Tubesheet has extensive on-site facilities, enabling us to provide our customers with the highest levels of product quality.

We made huge investments in our manufacturing facilities over the years and we continually invest in state-of the-art machines and advanced technologies.

Tubesheet has gained a reputation for utilising modern equipment which provides increased accuracy, higher production speeds and greater flexibility.

Sawing Capabilities

Tubesheet can produce plates up to 5000mm long and 120mm thick, cut using the very latest saw technology.

We have two automated CNC cutting machines enabling us to fulfil customer orders in fast turnaround times

Sawn tolerances can be as close as +/-0.25mm with an alignment feature ensuring all corners are exact and true at 90 degrees.

Discs up to 2200mm diameter x 200mm thick weighing up to 5 tonnes can be produced.

A computer optimisation programme plots best yield, enabling us to pass these cost savings onto our customers.

Machining Capabilities

Over the past 20 year’s we have invested in plant and machinery in excess of GBP5M and will continue to do so at the same or increased level. This allows us to maintain a strong competitive edge locally, nationally and worldwide.

We have the facilities to mill and drill components up to 3150mm long x 2100mm wide using CNC machining centres, giving us the ability to supply fully finished components from our material stock inventory or from customers’ free issue material.

Large and small turning capabilities are served by CNC and manual vertical borers and horizontal lathes allowing us to supply small threaded bar all the way up to tube sheets at 2000mm diameter.

We utilise two CAD systems which are regularly updated allowing us to receive electronic drawings for use to program all of our CNC machines. This can save valuable programming time and ensures the finished product exactly matches your drawing.

Lifting & Stock Level Facilities

Our crane, forklift and vacuum lifting capabilities enable us to readily handle a range of plate types and sizes, always ensuring that plates are produced to the highest quality standards.

In order to achieve the delivery times required by many customers, we hold up to 200 tonnes of stock. Our extensive range of material means we can cut and machine tube plates in-house, offering a finished product with a fast delivery time to any part of the world.

To complement our stock range, we can offer mill deliveries for “special” enquiries such as large diameter discs (up to 2m), in hot rolled condition for brass parts; or forged for copper nickel or aluminium bronze requirements.

All forged products can be delivered in forged, proof-machined or fully-machined condition.